The Indian paper industry boasts of an annual turnover of approximately $7 billion and is expected to grow at a rate that mirrors the growth of the Indian economy. This makes setting up a paper manufacturing mill a great business prospect.

However, finding a paper mill machinery manufacturer to partner with is easier said than done. You will need to find a manufacturer whose machinery can handle the production capacity you want, who offers proactive support, and whose machinery is efficient when it comes to the utilization of resources while still ensuring the overall quality of the end product is top-notch.

Top Paper Mill Machinery Manufacturer in India

Parason Machinery

Parason Machinery was founded in 1977 and is not just India’s leading paper mill machinery manufacturer, but is a name to reckon with in the paper manufacturing industry internationally.

Why Is Parason Machinery the Best?

Here are some of the reasons that put Parason clearly on top of the list of paper mill machinery manufacturers in India.

- We have more than 45 years of market experience in manufacturing and innovating machinery as well as spare parts for the paper industry.

- A presence in over 73 countries, gives Parason a unique perspective into the international paper manufacturing industry while stamping our authority as subject matter experts on all things related to manufacturing paper.

- In addition to manufacturing paper mill machinery, Parason Machinery is also a market leader in using the latest in metallurgical innovations to manufacture spare parts that are energy efficient and more durable than other manufacturers.

- Parason Machinery also offers consultation and turnkey services, designed to help new entrepreneurs set up successful paper manufacturing businesses and to help existing paper mills achieve milestones in production quality and quantity.

Machinery That Parason Manufactures

Parason Machinery manufactures machinery that is used to make several paper products, such as kraft paper, tissue paper, duplex board, writing paper, printing paper, molded fiber products, and specialty paper. Here’s a closer look at all the machinery we manufacture.

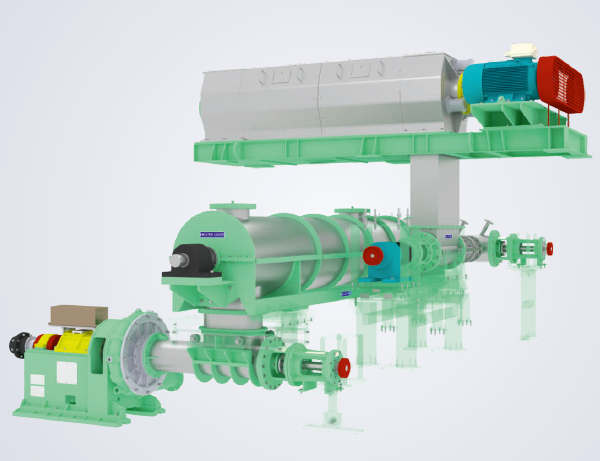

Pulping Machines

Pulping machines are crucial in paper manufacturing for breaking down raw materials like wood chips into pulp. This process involves separating fibers from other components, such as lignin, to create a fibrous mixture.

The resulting pulp serves as the foundation for paper production, enabling the formation of sheets through pressing and drying. Pulping machines play a key role in efficiently and effectively transforming raw materials into the essential pulp needed for various types of paper products.

Parason Machinery manufactures the following pulping machines:

- High consistency pulper

- Low consistency pulper

- Cup stock pulper

- Low consistency virgin pulper

- Ragger

- Wet strength pulverizer

- Dehydrating screw conveyor

- Grapple

- Trash pump

- Dilution pulper

- Fiber saver

- Tetra pack pulper

- Rope cutter

- Trommel screen

- Low consistency offset pulper

- Fiber guard

- Sharp Edge Drum Pulper

- UTM Pulper

- Reject Compactor

- Asymmetric Fiber Saver

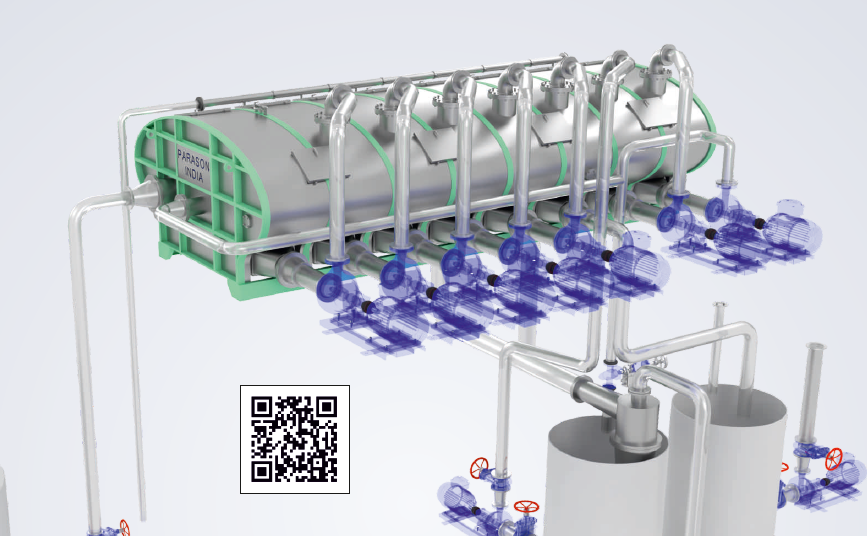

De-inking Systems

De-inking systems are used to remove old printing ink and other impurities from paper before it can be recycled to use for paper manufacturing. Parason Machinery manufactures both sand traps and de-inking systems.

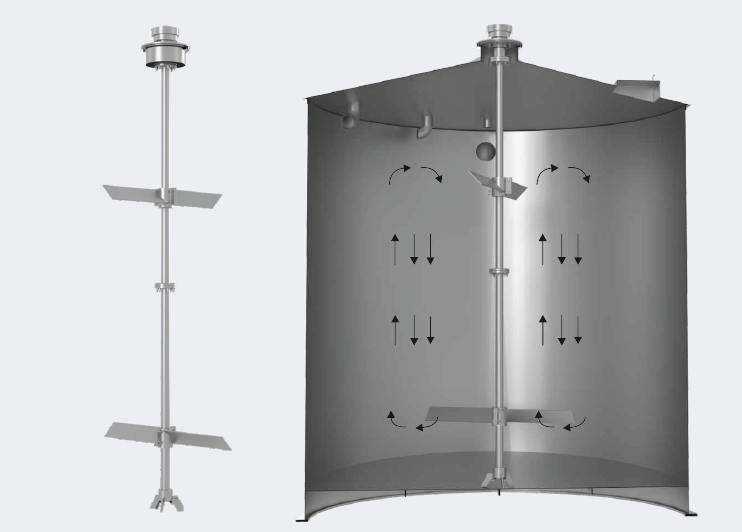

Agitators

In paper manufacturing, agitators are utilized to mix and suspend fibers and other components in the pulp slurry. These devices promote uniform distribution of chemicals and additives, ensuring consistent quality and properties in the papermaking process.

Agitators enhance the efficiency of various stages, such as pulp blending and chemical treatments, contributing to the overall homogeneity of the pulp mixture. This uniformity is essential for achieving desired paper characteristics and improving the manufacturing process’s reliability.

We at Parason Machinery manufacture two types of agitators: Vertical Agitators and Horizontal Agitators.

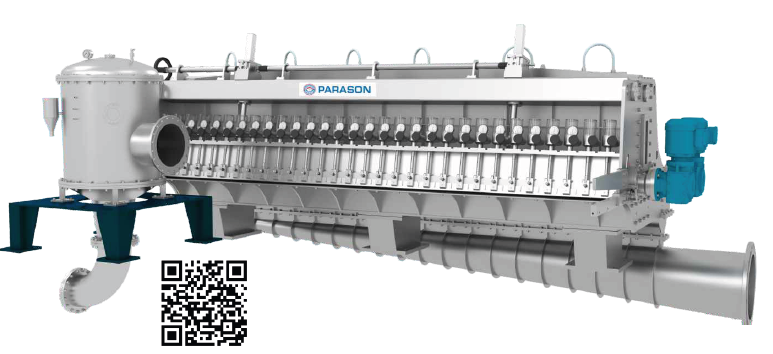

Headboxes

Parason Machinery manufactures two types of headboxes: Hydraulic headboxes and pressurized headboxes.

Headboxes play a key role in determining paper quality, thickness, and uniformity by precisely regulating the pulp flow onto the forming wire, ultimately affecting the characteristics of the final paper product.

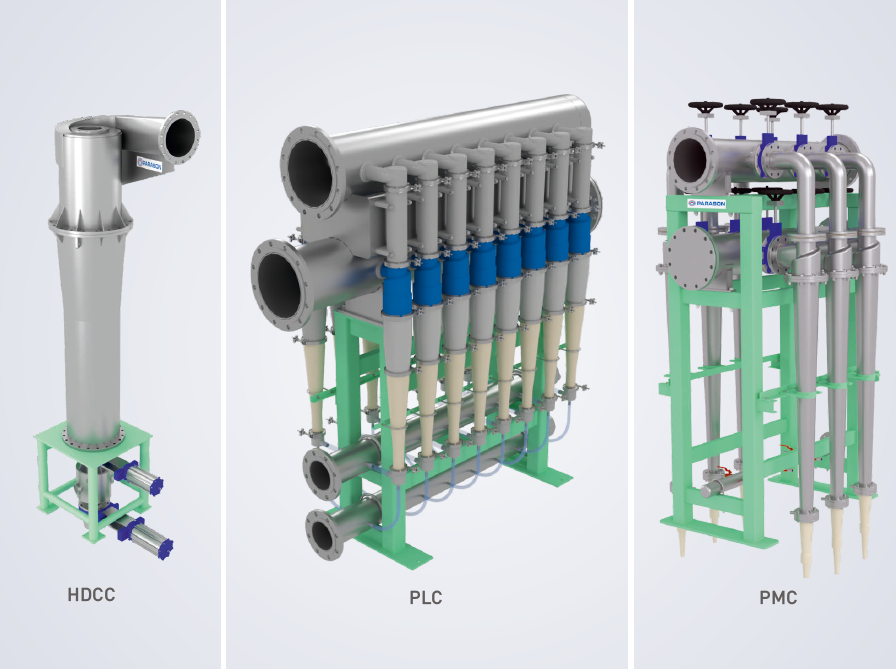

Cleaners

We manufacture high-density cleaners, low-density cleaners, medium-consistency centric cleaners, and twin-screw sand separators.

These cleaners are used to remove contaminants from the pulp, improving the overall quality of the final product.

Thickening

Parason Machinery manufactures three thickeners. These are: Folded Thickener, Gravity Disc Thickener, and Decker Thickener, Parason Disc Filter, Double Nip Washer .

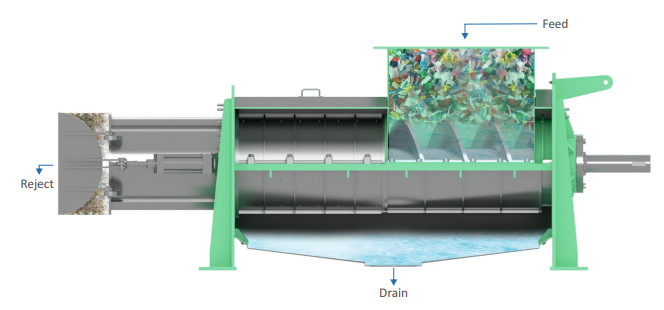

Reject Handlers

Reject Handlers are important in the paper manufacturing process as they help remove impurities from the pulp. We at Parason manufacture Reject Compactors, Sand Separators and Reject Screw Press, Pan Press.

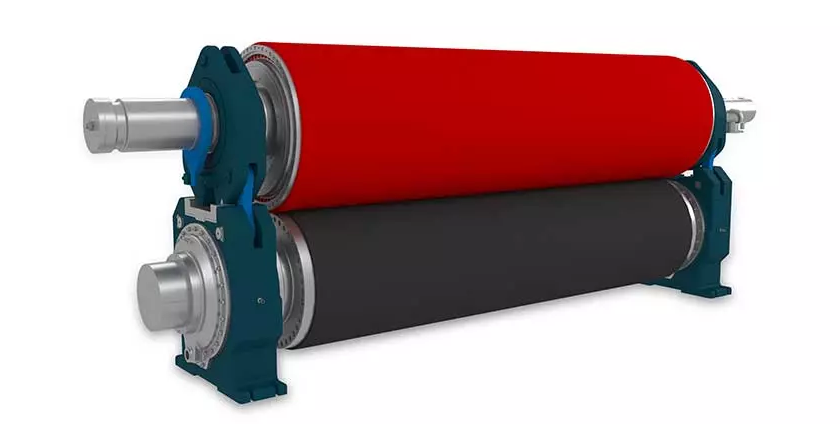

Paper Machines

Parason Machinery has a world-class paper machine in the Parason Maxi Shoe Press. This paper machine is more energy efficient, more durable, easy to integrate with existing machines, fully automated and has a high output.

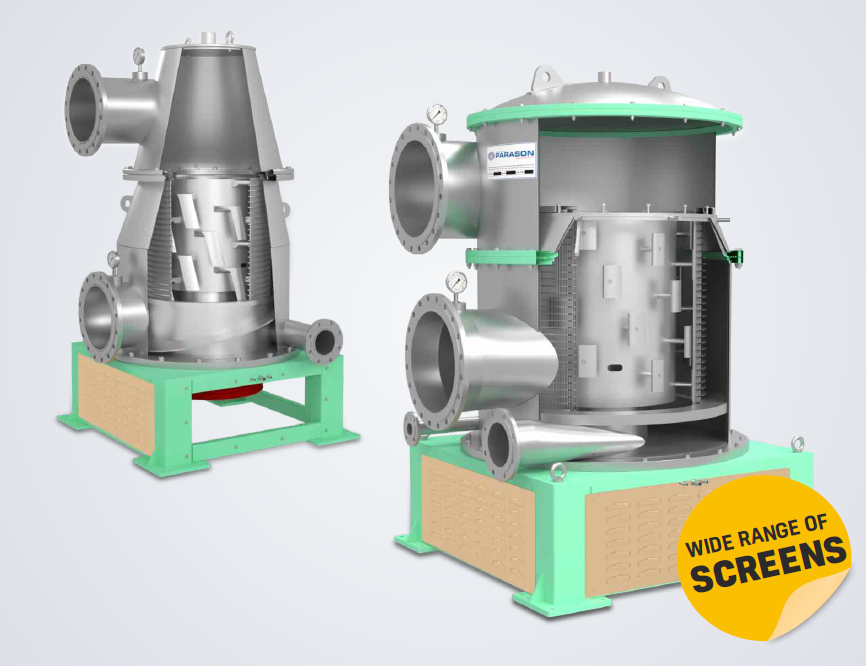

Screening Machines

Screening machines are used to remove large knots, debris and oversized fibers from the pulp slurry. Parason manufactures 11 different screening machines for you to choose from.

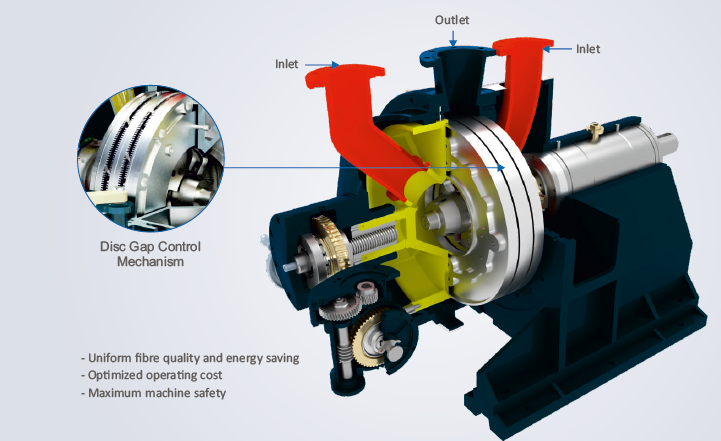

Refiners

Refiners are used in paper manufacturing to mechanically treat the pulp and improve the quality of the fibers. Parason Machinery manufactures three different types of refiners: Trapmagni, Confiners and Twin/Tri disc refiners.

Effluent Treatment Plants

The paper manufacturing process produces multiple effluents. We manufacture effluent treatment plants to help our clients reduce the negative impact of these effluents on our surroundings.

The effluents treatment plants Parason manufactures are: Spray filter fractioning systems, belt filter presses and Dissolved air flotation water treatment machines.

Dispersion Systems

Dispersion systems contribute to the efficient incorporation of additives, improving the overall quality and consistency of the paper. They play a key role in enhancing paper characteristics and meeting specific performance requirements during the manufacturing process.

At Parason Machinery, we manufacture mini dispersers, a hot disperser system and an oxidative bleaching tower.

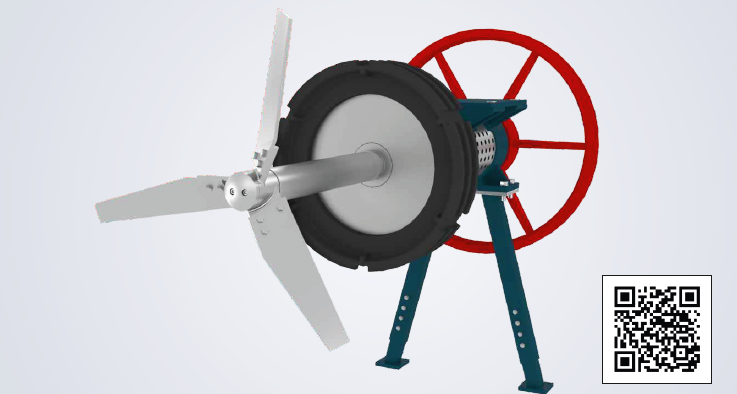

Deflakers

Deflakers play a crucial role in refining and breaking down fibers within the pulp. These machines, known as deflaking or defiberizing equipment, use mechanical forces to disintegrate fiber bundles and individualize the fibers.

By doing so, deflakers improve the flexibility and bonding properties of the fibers. This process contributes to the creation of a more uniform and fine pulp, enhancing the overall quality of the paper.

Parason Machinery manufactures hole-type deflakers, ring-type deflakers, and conical-type deflakers.

Spare Parts Parason Manufactures

Parason Machinery uses the latest advances in technology and metallurgy to manufacture spare parts that are energy-efficient, affordable, and capable of handling more than regular wear and tear.

Our spare parts work great not just on our machines, but on most machines used in the paper manufacturing industry.

Here are the spare parts we manufacture.

- Refiner plates

- Screen baskets

- Rotors

- Shaft sleeves

- Agitator blades

- Rotating assemblies

- Gear boxes

- Impellers

- Screen plates

- Screws

Services and Solutions Parason Machinery Offers

Parason Machinery also offers specialized services and solutions to enhance various aspects of operating a paper mill.

We have four different audits that are aimed at identifying inadequacies in different processes that are a part of the paper manufacturing process and helping our clients overcome these hurdles. These audits are:

- Screening Audits

- Refining Audits

- Paper Machine Audits

- Pulp Mill Audits

We also offer end-to-end turnkey solutions to those looking at setting up new paper mills, existing mills looking to expand their current scale of operations, and more.

The scope of these turnkey solutions encapsulates everything from planning plant layouts, engineering services, and capacity planning to setting up raw material supply chains, and providing automation solutions, all the way to ensuring our clients have successfully set up and are sustainably operating a paper mill.

Partner With Parason Today to Set Up Your Paper Mill

Whether you’re looking at an end-to-end solution to help you set up a new plant, expand the production capacity of your existing plant or simply update the machinery in your plant to improve the quality and quantity of the paper output, you need to look no further than Parason Machinery.

With over 4 decades of experience and more than 186 successful projects around the world, you’d be hard-pressed to find a better machinery manufacturer to help set up your paper mill.

Get in touch with our team today, and we’ll help make your paper mill dreams a reality.