Introduction to Pressure Screens in the Paper Industry

In the dynamic realm of the paper industry, where precision and efficiency reign supreme, the screening process stands as a pivotal stage in stock preparation. It is within this stage that impurities are meticulously filtered out and fibers are separated by Pressure Screens in the Paper Industry, ensuring the quality and integrity of the final product.

In this blog let’s delve into the important information about the screening process and the Pressure Screen.

Understanding the Screening Process

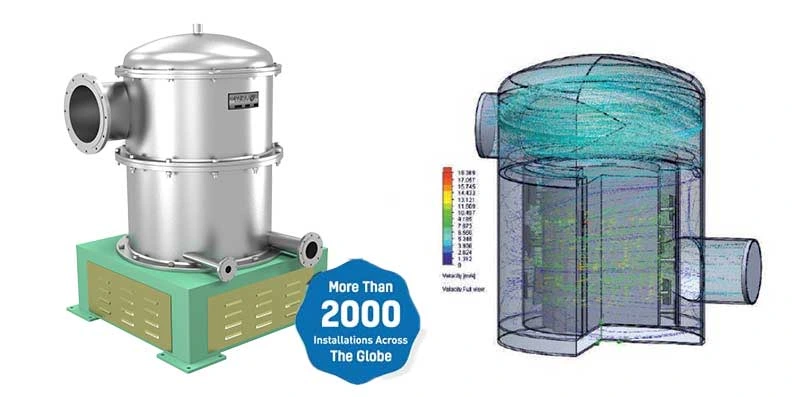

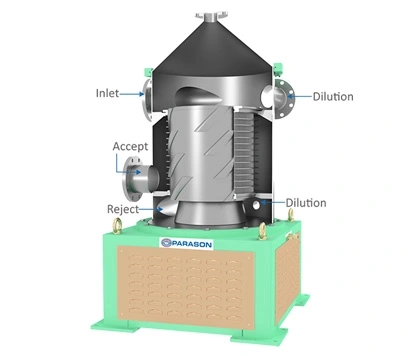

In the process of paper production, pressure screens play a crucial role. These sophisticated machines contain screen basket, a rotor, within their core, serving as the primary agent of filtration. With an inlet for suspension, an outlet for accepted stock, and a discharge for rejected stock and contaminants, pressure screens orchestrate the intricate ballet of separating the desirable fibers from unwanted impurities.

The Mechanism Behind Pressure Screens

Let’s have a look at how Pressure Screens in the paper industry work.

During operation, the pulp enters the upper part of the pressure screen’s separation chamber in a tangential direction from the inlet pipe. As it flows in, the heavier impurities are separated due to centrifugal force and settle at the bottom tank, where they are discharged from the port. Meanwhile, the pulp overflows the circular weir plate and enters the screening area located between the screen basket and the rotary drum.

Here, the pulp undergoes further screening. The qualified pulp, which is free from impurities, is discharged from the receiver’s mouth through the screen basket. On the other hand, the unqualified pulp, still containing impurities, continues to move downward and is eventually discharged from the discharge pipe.

Advantages of Pressure Screens in the Paper Industry

Reduced Installation Power & Higher Production Capacity

One of the hallmark advantages of pressure screens lies in their ability to deliver heightened efficiency while minimizing resource consumption. With reduced installation power requirements and an amplified production capacity, these stalwart machines pave the way for streamlined operations and enhanced productivity.

Inflow Structure for Low Pulsation

The clever design of pressure screens incorporates an inflow structure engineered to mitigate pulsation—a common concern in screening processes. This innovative feature ensures a smoother, more consistent workflow, contributing to the overall stability and reliability of the production line.

Seamless Connection and Minimal Maintenance

A notable advantage of pressure screens lies in their seamless integration into the production pipeline. With no gaskets required and a meticulously polished pulp outlet companion flange, these machines facilitate a seamless connection, free from the risk of fiber hitching. Moreover, with automatic oil injection devices and seal water detection alarm systems in place, the operational safety and maintenance requirements of pressure screens are markedly reduced.

Sturdy Construction for Long-Term Reliability

Crafted with an advanced structure and built to withstand continuous operation, pressure screens epitomize durability. Their sturdy construction, coupled with convenient disassembly and assembly features, ensures minimal downtime and fewer malfunctions—a testament to their reliability and longevity in the demanding landscape of paper production.

Ideal for Approach Flow Screening Systems

In the realm of approach flow screening systems, pressure screens emerge as the epitome of efficiency and effectiveness. Their high throughput capabilities, coupled with lower energy consumption, make them the preferred choice for achieving optimal results in this critical stage of the production process.

Superior Fiber Recovery and Quality Assurance

With pressure screens, paper manufacturers can rest assured knowing that their operations are optimized for superior fiber recovery and quality assurance. By minimizing rejects and maximizing the obtainment rate of long fibers, these formidable machines uphold the highest standards of excellence, ensuring the production of top-tier paper products.

Other Screening Machines

While pressure screens hold a prominent position in the paper industry, they are not alone in their quest for optimal screening efficiency. Various other pressure screening machines complement their efforts, each wielding unique capabilities and applications tailored to specific needs within the production line.

Inflow Pressure Screen

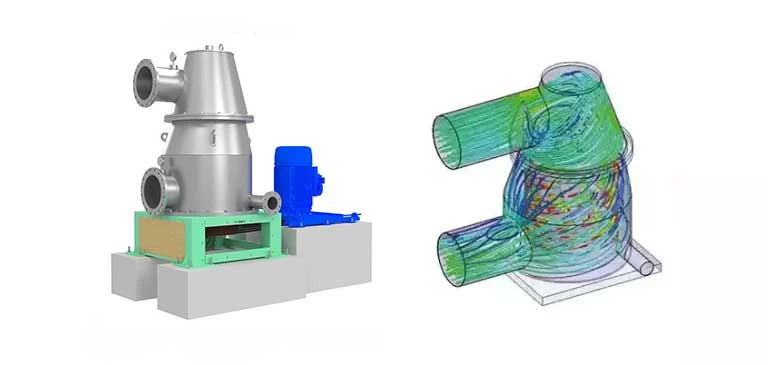

Low Consistency Screen

The screens are ideal for both the stock preparation system and the approach flow system. Thanks to the ROTOR design, the screen operates smoothly without pulsation. The distinctive contoured multi-foil rotor, with its optimal foil angle, guarantees improved screening efficiency and reduces reject thickening.

Combo Screen

The Combo Screen efficiently handles light rejects, deflakes stock, and cleans and dewaters fiber simultaneously. Pulp enters tangentially through the inlet. The perforated plate and bottom impeller effectively deflake and clean the stock. Accepts pass through to the remaining light rejects, while fiber moves to the upper chamber for fine separation. All rejects are separated in this zone, yielding accepts.

Medium Consistency Screen – Vertical

The Parason Medium Consistency Screen features a uniquely designed rotor, available with either a hole or slotted basket. The rotor, with its specially crafted and contoured foils, produces minimal positive pulses and elevated negative pulses. As a result, it consumes less energy and provides a more effective purging action to maintain the cleanliness of the basket.

Shield Screen

The Parason Shield Screen offers a dependable screening solution for efficient paper production. With its newly developed design, the Parason Shield Screen ensures effective screening during the approach flow stage. Optimized head geometry and machine housing contribute to enhanced productivity of the Shield Screen.

Positioned eccentrically, the screen basket prevents deposits and stringing due to uneven flow patterns. The Parason Shield Screen provides operational reliability at a lower cost.

Conclusion

In the tapestry of the paper industry, pressure screens stand as stalwart guardians of quality and efficiency. With their unrivaled capabilities and myriad advantages, they continue to shape the landscape of paper production, driving innovation, and ensuring the delivery of superior products to consumers worldwide.

Parason Machinery provides the cutting-edge technology for your paper mill machinery. Connect with us for more details and enquiries related to pressures screens as well as our other products for your paper mill.