Advanced Detrashing Systems for Enhanced Pulping

Pulp extraction is an essential part of the paper manufacturing process. The quality of the end product often depends on the quality of the pulp that is extracted.

However, paper manufacturers are often faced with problems during pulp extraction. They find themselves unable to either extract enough pulp, or that the pulp being extracted has contaminants in it.

One of the solutions used to tackle both of these problems is the detrashing system. Here’s a quick read, introducing you to advanced detrashing machines for enhanced pulping capabilities.

The Role of Detrashing in the Pulping Process

Detrashing in the pulping process refers to the removal of impurities and non-fibrous materials from raw materials like wood or recycled paper, to produce a cleaner and higher-quality pulp. The detrashing step is a crucial stage in the pulp and paper manufacturing process, as it directly influences the quality and efficiency of subsequent processes.

The pulping process involves breaking down raw materials into homogeneous mixture of water and fibers that can be used to produce paper after processing. Detrashing is necessary to eliminate unwanted elements that may hinder the quality of the final product. These impurities can include bark, stones, wires, metal, plastics, and other contaminants that may be present in the raw materials.

The detrashing process typically involves several stages, including screening and cleaning. Efficient detrashing has several benefits for the pulping process and the quality of the final paper product. It helps maintain the integrity of the papermaking equipment by reducing wear and tear caused by abrasive contaminants.

It also enhances the quality of the pulp by minimizing contaminants percentage and reducing the likelihood of defects in the final paper. Additionally, detrashing improves the overall efficiency of the pulp and paper mill by preventing equipment damage, reducing downtime, and optimizing pulp quality.

Machines Used for Detrashing

Detrashing systems in the pulp and paper industry rely on a variety of specialized machines to efficiently remove impurities and non-fibrous materials from raw materials. Here are some key machines commonly used in detrashing systems.

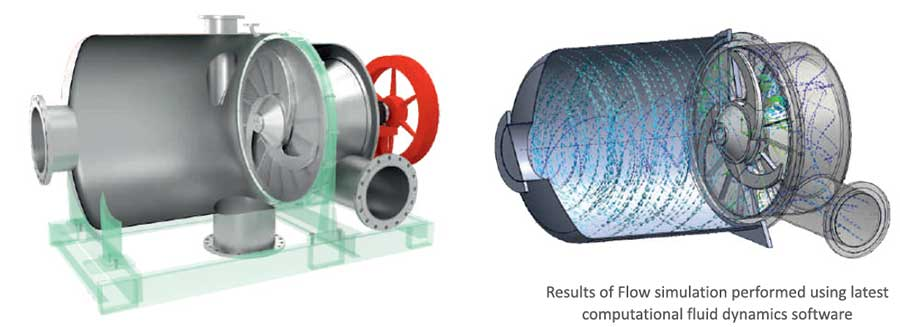

Asymmetric Fiber Saver

The Asymmetric Fiber Saver machine utilizes an asymmetric design to effectively separate fibrous materials from contaminants. It plays a crucial role in maintaining the quality of pulp by preventing unwanted materials from entering the pulping process.

The Fiber Saver (AFS) is a sophisticated machine used in detrashing systems. The AFS employs advanced technology to optimize the detrashing process, ensuring a high level of purity in the pulp.

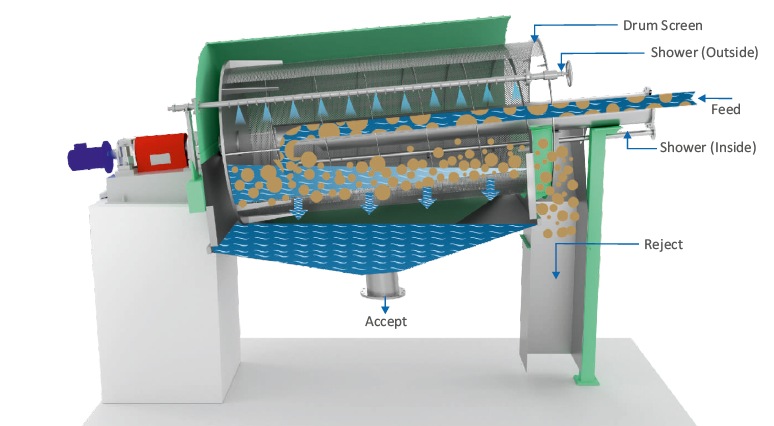

Inclined and Horizontal Trommels

Trommels are cylindrical screens that rotate to separate materials based on size. In the detrashing system, both inclined and horizontal trommels are used to screen out impurities. Inclined trommels rely on gravity to assist in the separation process, while horizontal trommels use rotation to achieve the removal of heavy reject like tetra pack in the cyclic oprations. These machines efficiently remove larger contaminants from the raw material.

Other Machines

Here are some other machines that may be used during the detrashing process.

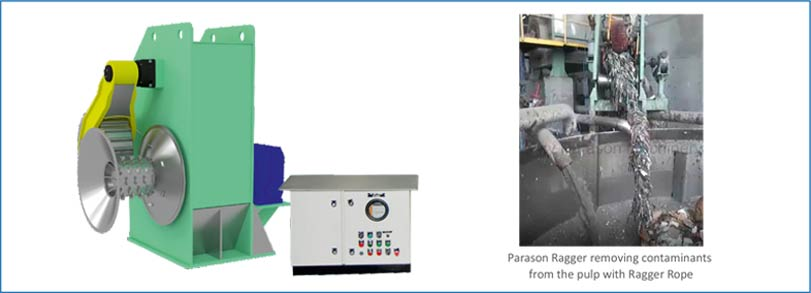

● Ragger

● Rope Cutter

● Grapple

● Junk Trap

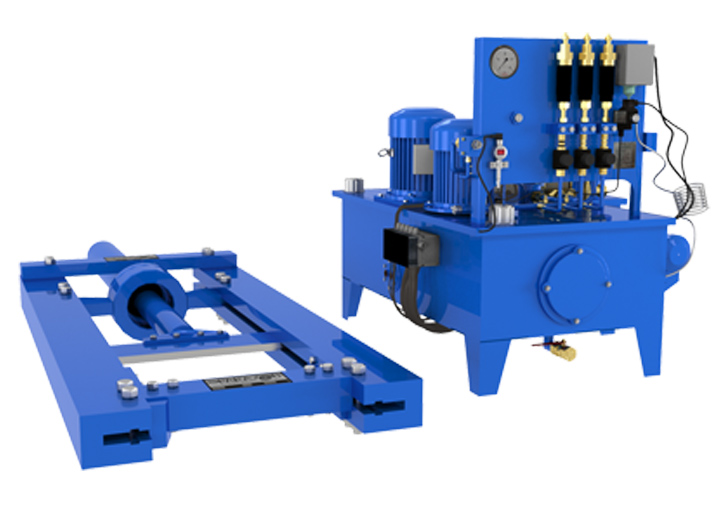

Parason Fiber Guard: Combination of an AFS and Trash Pump

The Parason Fiber Guard (PFG) plays a pivotal role in the journey of stock suspension from the pulper. It handles stock with impurities and contaminants, utilizing the pressure generated by the rotor to efficiently separate contaminants. The disintegrated fibers are then directed to the screening stage.

Advantages

Here are some of the advantages of choosing the PFG for your detrashing needs.

- Tailored for the wet preparation of waste paper, ensuring optimal processing.

- Removes impurities with minimal fiber loss, maintaining quality.

- Prevents pulp jamming in subsequent operations, enhancing workflow efficiency.

- Energy-efficient design leads to cost savings and requires low maintenance, maximizing productivity.

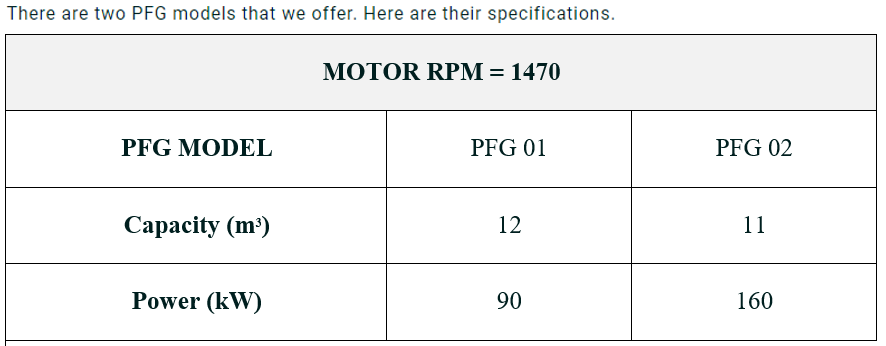

Main Specifications:

Enhance Your Pulp Quality With Parason

Parason Machinery has around 5 decades of experience in manufacturing cutting edge paper mill machinery and wear parts, leading to a presence in more than 60 countries and reputation as a global leader in the paper industry.

Whether you’re looking for an efficient de-trasher, other pulping machines or indeed, any machinery and spare parts you need for your paper mill, you need to look no further than Parason Machinery.

Contact us today for all your paper mill machinery needs, or to take advantage of our turn-key solutions. We’ll make sure your production as well as product quality are both enhanced and optimized.