We live in a time where people and indeed, entire governments are becoming aware of the impact their choices make on the environment. For example, as many as 99 countries have banned single-use plastic bags. Canada, on the other hand, has completely banned all single-use plastics.

These decisions have forced businesses to change their outlooks and to start making more ecologically conscious decisions as well. One such example is how a lot of restaurants and takeaways have migrated from using plastic containers to molded fiber clamshell containers for packaging.

As a result, manufacturing molded fiber clamshell takeout containers is now a huge opportunity, especially for those already in the paper manufacturing business. The global molded fiber manufacturing business is growing at a CAGR of 4.82% and is expected to be valued at $5.88 billion by 2030.

For those of you interested in making the most of this rapidly expanding market opportunity, here’s a guide to molded fiber clamshell takeout containers.

An Introduction to Molded Fiber Clamshell Takeout Containers

Molded fiber clamshell takeout containers have become increasingly popular in recent years as an eco-friendly alternative to traditional plastic and Styrofoam containers. These containers are used for packaging a variety of food items, ranging from salads and sandwiches to hot meals.

In this blog post, we will explore the characteristics, advantages, and manufacturing process of molded fiber clamshell takeout containers.

Advantages of Molded Fiber Clamshell Takeout Containers

Using molded fiber clamshell containers comes with definite advantages. Here are some of them.

Eco-Friendly

Molded fiber clamshell containers are made from renewable and sustainable materials, usually recycled paper or pulp. This makes them a more environmentally friendly option compared to traditional plastic containers.

Biodegradable

One of the key advantages is their biodegradability. Unlike plastic, molded fiber containers break down naturally over time, reducing the environmental impact of food packaging.

Insulation Properties

These containers offer decent insulation, keeping food warm or cold as needed. This feature makes them versatile for various types of cuisines and temperatures.

Customization

Molded fiber clamshell containers can be easily customized in terms of shape, size, and design. This allows restaurants and food businesses to showcase their brand identity through packaging.

Microwave Safe

Many molded fiber containers are microwave-safe, providing convenience for both consumers and food establishments. This feature enhances the usability of these containers for reheating purposes.

Manufacturing Molded Fiber Clamshell Takeout Containers

Let’s now take a look at the process of manufacturing molded fiber clamshell takeout containers.

Materials Used

The primary materials used in manufacturing molded fiber clamshell containers are recycled paper or pulp. These materials are chosen for their sustainability and ability to be molded into various shapes and sizes.

Manufacturing Process

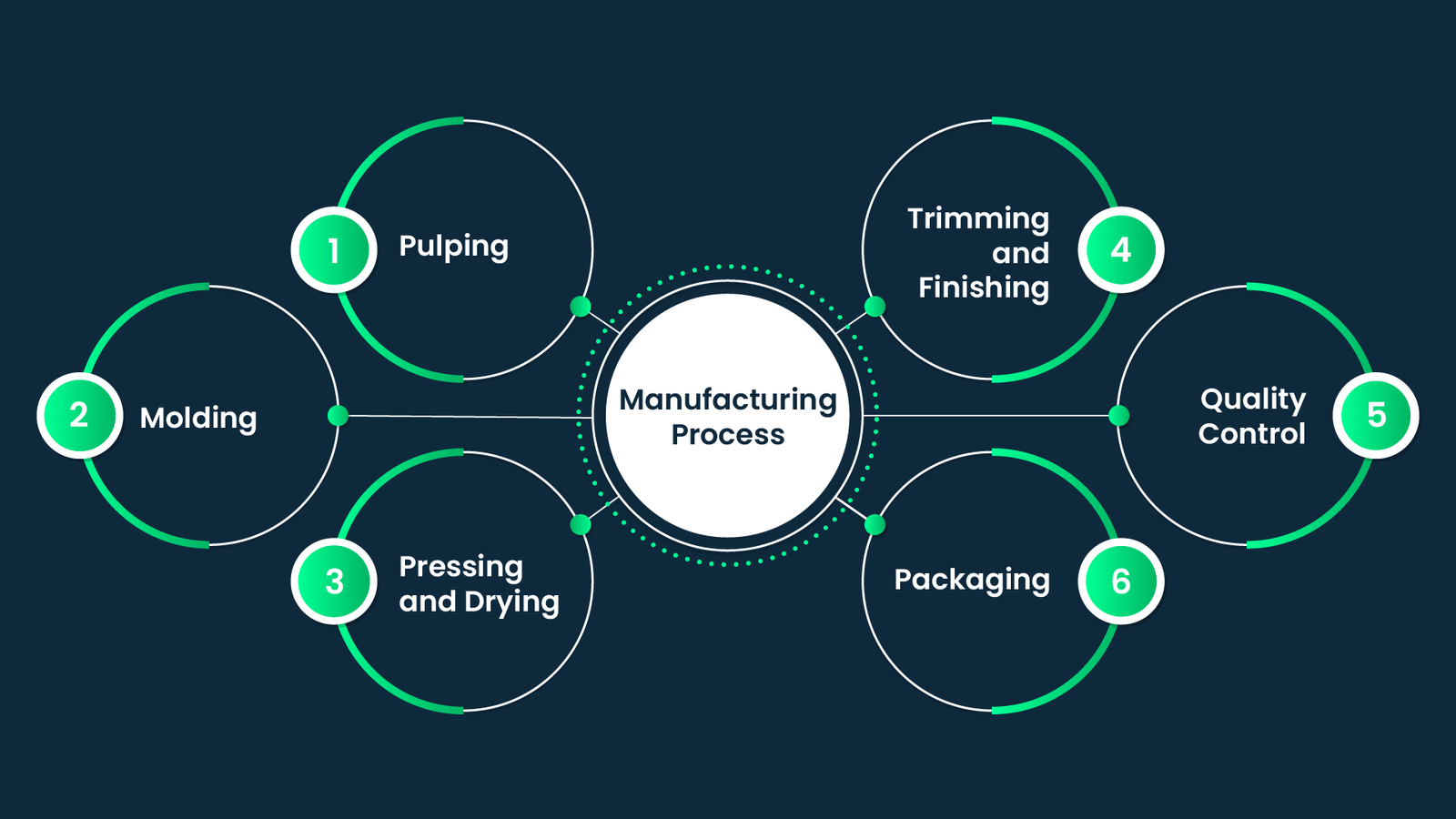

Let’s dive into the manufacturing process for molded fiber clamshell containers.

Pulping

The process begins with collecting recycled paper or pulp, which is then broken down into a slurry through pulping. This mixture forms the base material for the containers.

Molding

The pulped material is then shaped into the desired clamshell form using molds. This process can be adjusted to create containers of different sizes and shapes according to customer specifications.

Pressing and Drying

The formed containers undergo a pressing stage to remove excess water. Subsequently, the containers are dried thoroughly, ensuring their structural integrity and stability.

Trimming and Finishing

After drying, the molded fiber containers go through a trimming process to achieve the final shape. Any excess material is removed, and the edges are finished for a polished appearance.

Quality Control

Rigorous quality control measures are implemented throughout the manufacturing process to ensure that the molded fiber clamshell containers meet industry standards. This includes checking for proper molding, thickness, and overall quality.

Packaging

Once the containers pass quality control, they are packaged and prepared for distribution. Some manufacturers may offer additional customization options, such as printing logos or branding on the containers.

Manufacture Molded Fiber Clamshell Containers With Parason

Parason Machinery has been at the forefront of manufacturing all the machinery needed to produce molded fiber products, such as clamshell takeout containers. Our products include hRobotic Integrated Forming Machines, Semi-Automatic Forming Machines, Production Molds, Edge Trimming Machines, Packaging Solutions, Pulpers and more.

Our machinery and spare parts have a reputation for being able to handle more than the regular amount of wear and tear, guaranteeing that your maintenance costs are minimized. Additionally, all our machinery is designed to be energy-efficient, ensuring minimal wastage and minimizing energy costs.

Leverage our team’s expertise in not just manufacturing, but also in helping our clients set up every aspect of their molded fiber manufacturing plants by contacting us today.